Toyota Production System

An Integrated Approach to Just-in-Time

Note: All the pictures used on this page are extracted

from Toyota Production System, An Integrated Approach to

Just-in-Time book. I have written the page numbers in the

braces from where these pictures were taken.

I acknowledged the text used from this book by using

quotes around that text and also mentioned page numbers in

braces.

Book Review:

Are you interested to work in an automobile industry or

setup your own automobile industry like Elon Musk, this is

the right book to read! Be a little cautious if you are

thinking about doing the later as the automobile industry in

USA is very heavily crowded.

After 1973 oil crisis imposed by Organization of Arab

Petroleum Exporting Countries, Toyota Productions systems

implemented and promoted a Toyota Productions Framework.

"The main purpose of the system is to eliminate through

improvement activities various kinds of waste lying

concealed within a company." (page 3)

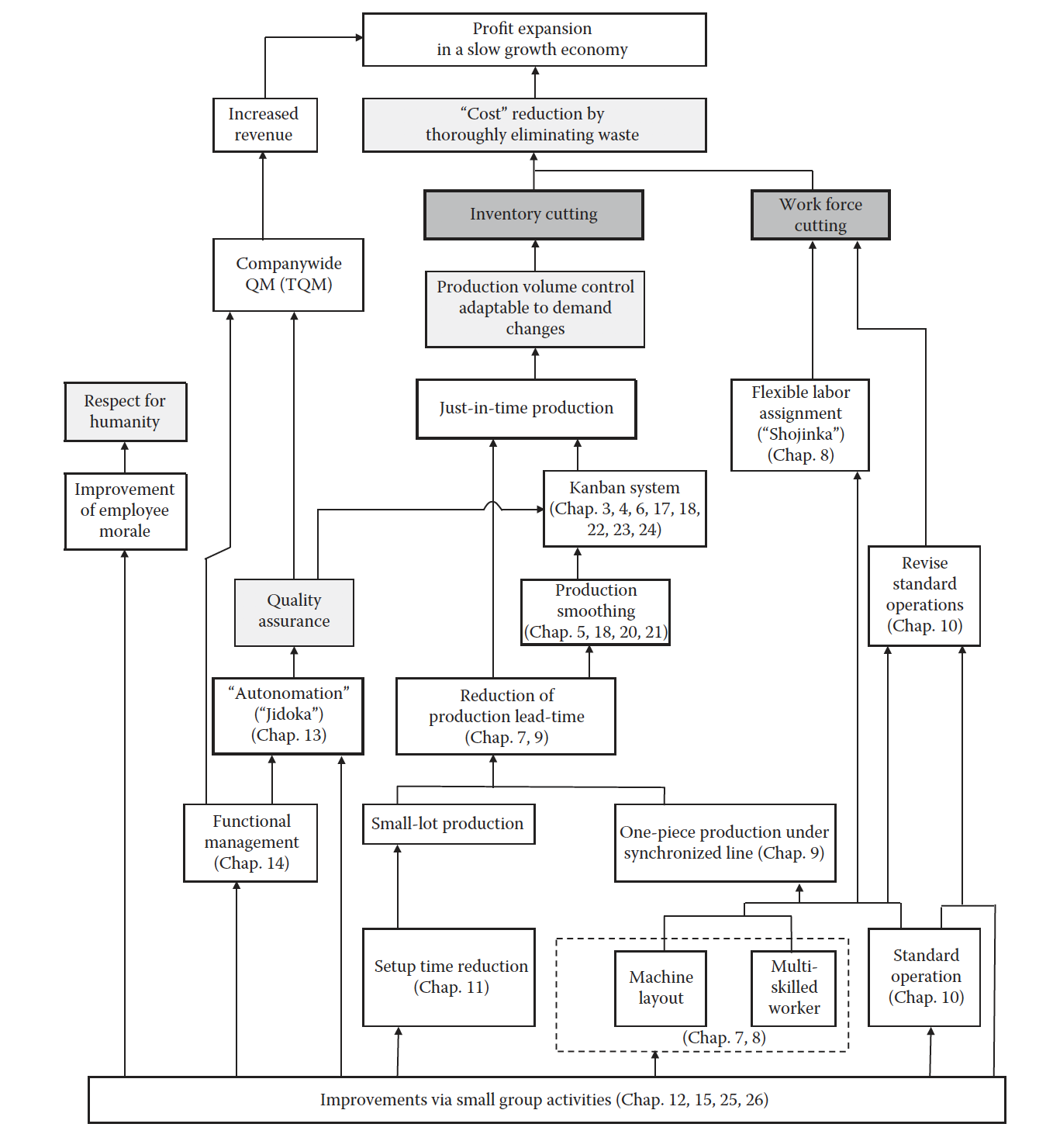

The author starts of his first chapter by primarily focusing

on various important aspects on which total framework of the

Toyota production systems lies on. He highlights topics such

as primary purpose, kanban systems, production smoothing,

shortening setup time, process layout for shortened lead

times and one-piece production, standardization of

operations, autonomation, improvement activities, the Goal

of TPS. Later in the first section of his book, he talks

about how Toyota achieved its primary goal of profit through

cost reduction by employing good strategies like elimination

of overproduction, limiting excess inventory and

overproduction, reducing unnecessary capital investments.

In the second section of his book, the author talks about

all the subsystems of Toyota production systems which should

function effectively to achieve all the goals prescribed in

the first section of his book. He talks about introduction

of supplier kanban, smoothed production, information system

for supply chain management in depth. Concepts like 5S

concept which is used to manage slack in an automobile

company, shortening of production time, standard operating

procedures and machine layout are very centric to automobile

industries. A person from another industry may not find it

very useful knowing in depth about these concepts but it

would little useful to know the summary of these concepts

as these concepts can be generalized and used everywhere in

the world. One of the best chapters of this book is about

“One-Piece Production”, the author describes it as “the

concept of having things flow smoothly through the factory

one by one, like water, without any holdups” (page 161).

One-Piece Production can also be implemented in software

engineering with little modifications and it would have a

very good positive effect on the quality of software

delivered. I personally feel that One-Piece Production has

few traits of waterfall model of software development.

Section three of this book was quantitively approached. The

author states few terms like Sequencing method, Goal Chasing

method I & II, computing number of kanbans, he gives

formulas to compute those terms quantitively. He gives us

very good examples of his own or detailed study of Toyota

companies for each term used and that makes it very easy to

understand those terms and their usage. Last section of

this book deals with management of human resources. Few

concepts like “Kaizen Mindset” are very well explained by

the author. He later talks about various topics relating to

improvement of workforce and reduction of workforce and

autonomation of several tasks.

This book is a very good book to know about various

subsystems of an automobile industry. The author states

the concepts theoretically and complements it with a

detailed case studies of any of the Toyota companies or

some made-up examples for easy understanding. It is little

difficult to create any analogies between automobile

industry and IT industry for few of the concepts of this

book otherwise it is a good book to read and know about

various processes of an automobile industry.