Usage and Importance of Kanban

Source: Kanban, Successful Evolutionary Change for Your

Technology Business by David J. Anderson

Definition:

Kan-ban is a Japanese word that literally means "signal card" in

English. In a manufacturing environment, this card is used as a signal

to tell an upstream step in a process to produce more. The workers at

each step in the process are not allowed to do work unless they are

signaled with a kanban from a downstream step.

The signal to pull new work is inferred from visual quantitiy of

work-in-progress subtracted from some indicator of the

limit (or capacity).

Most important principles required to make quality software development

- Visualize Workflow

- Limit Work-in-Progress

- Measure and Manage Flow

- Make Process Policies Explicit

- Use Models to Recognize Improvement Opportunities

Why should we use kanban?

- Focus on Quality

- Reduce Work-in-Progress

- Deliver Often

- Balance Demand against Throughput

- Prioritize

- Attack Sources of Variability to Improve Predictability

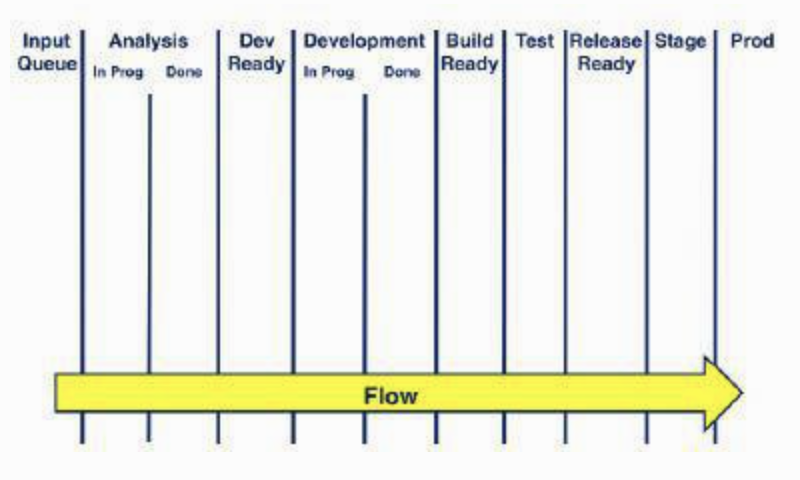

Implementing kanban

- Decide the outer boundaries of the kanban system. It is often best to limit this to the immediate span of political control.

- Model the card wall to align with the boundary decision made regarding limiting WIP and visualizing work.

- Define work types and model how their work flows. Some types of work may require every step in the flow.

-

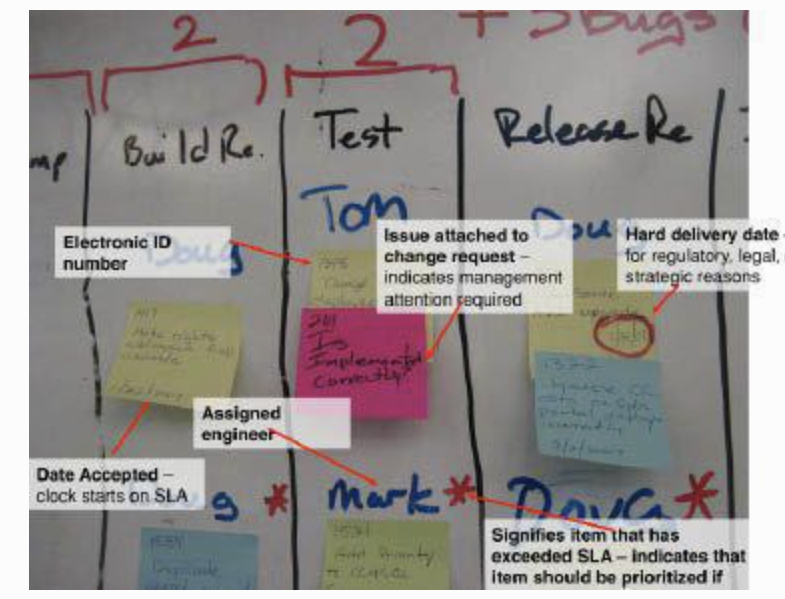

Design the work item card to have enough information to faciliate

self organization for pull and to enable team members to make good

quality decisions with respect to risk based on work item type,

service-level agreements, and classes of service.

Anatomy of an item card -

Use an electronic tracking tool if the team is distributed.

Examples of electronic tracking tools are Lean Kit Kanban, Agile Zen, Target Process, Silver Catalyst, RadTrack, Kanbanery, VersionOne, Greenhopper for Jira and Flow.io. - Discuss methods for handling concurrency in activites and choose how to model and visualize them

- Discuss methods for handling activites that do not need to follow a specifially ordered flow and choose how to model and visualize them.

Coordinating with kanban systems

- Using both physical card wall and an electronic tracking system.

- Having regular meetings will reduce the coordination cost for those meetings and improves attendance.

-

Daily standup meetings should be used to discuss issues,

impediments, and flow.

Daily standups also encourage a culture of continous development. - Grooming the backlog with regular triage to reduce its size improves the effectiveness and efficiency of prioritization meetings.

- Escalation paths and policies should be clearly defined.